Mitch is right on... You can never protect against every scenario that is possible in racing. Each person has to choose their own comfort level and no one is completely right or completely wrong in their decision.Originally Posted by mitchntx

Mitch is right on... You can never protect against every scenario that is possible in racing. Each person has to choose their own comfort level and no one is completely right or completely wrong in their decision.Originally Posted by mitchntx

James Proctor

http://www.jp-motorsports.com

It is nearly impossible to factor in all the possibilities involved in a crash... for example what if there was a barrier to prevent the car from getting into the trees??? At a SCCA event at Cabiness (an airport for those not familiar) the track was deemed very safe because it was wide open with very few obstructions, however, a car had a stuck throttle, went flying across the course and hit a tractor, killing the driver... how do you account for that??? In this case, how do you factor in "passing out behind the wheel"???

How about the exhaust that went through the windshield at NPR? If it would have hit directly in front of the driver would the plastic visor save a life?

Don't get me wrong I'm all for safety in fact I'm willing to bet the cage in my car is the safest in the field including having my seat mounted on a framework of tubing welded directly to the cage... When is it overkill??? How many of you have the base of your seat support tied DIRECTLY to your cage??

We are so obsessed with safety on the track and yet we send our wives and kids out on the highways with overweight 18 wheelers out of Mexico that have bald tires and defective brakes...

On a lighter note if everyone drove a an overweight pig like the 27 car and kept your speed down (like I do) things might be a little safer :twisted:

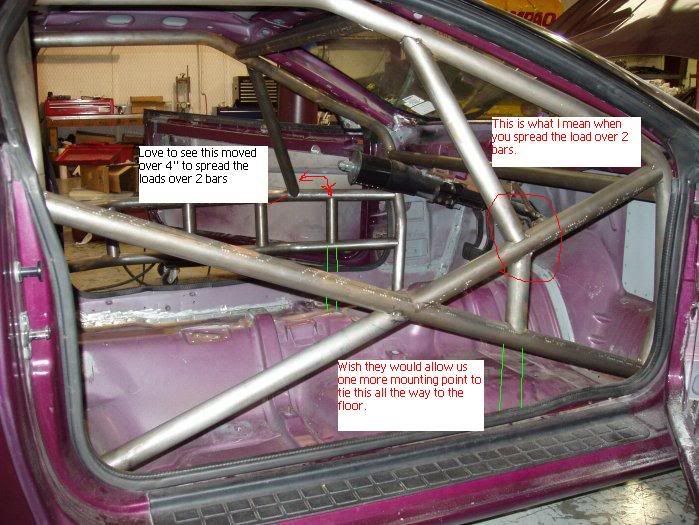

A little bit of triangulation and that cage wouldn't have failed. The obvious idea is to spread the loads over the greatest surface area, bars, gussets, floor plates etc... If you look at the triangulation and load spreads of the rear sections of the Audi cage, it held perfectly, and the seat didn't move. The front failed more than anything because of the long unsupported/untriangulated span.

The one thing that I really wish NASA would change is the number of floor mounting points. Like in Glenn's picture, spreading the down force loads over 2 bars is much better than one, taking that load all the way through 2 bars and into a floor plate tied into the rocker panel and your even better. So much of NASA/SCCA cage rules seem to be geared to limit any "competitive advantage" gained by making the structure more riged. The result is that some of the cage designs out there, while perfectly legal, are not safe, and some of the safest cage designs are not legal. With all of the dirt cars I have built in the past, I always take the forward upper support to the vertical door bar support, then all the way to the frame, IMSA doesn't disagree and I have seen some of my cars take side hits that would cave in a lot of the cars I have raced with in NASA/SCCA.

If you are using a unibody and the factory floor structure/rocker panels and trans tunnel are sound and the cage mounting points are located in the hard points of the unibody structure, there is really no need to tie the bottom seat mounts into the cage. If you are using a body on frame car and the cage ties to the frame and not the body (as it should), you MUST mount the seat to the cage/frame stucture, never ever ever ever ever do you mount a cage to a frame and the seat to the body on a body on frame car. Think about it, the body will move in an impact seperate of the frame/cage structure, your seat bottom and lap/crotch belts are moving with the body, the seat back and shoulder belts will be moving with the frame/cage. One direction of impact, your belts will get slack, the other direction and your belts will kill you. Neither is good.

The real moral to the story, if you don't know the engineering behind what goes into cage design, have someone who does build your car. After all, this is a hobby.

Dave - Lou was politicing a rules change w/ NASA while i was building that cage. i did things as if it was gonna happen. the plan was to do as you pointed out w/ the two triangulated bars and w/ the side bars on the driver side door bars. we also almost made "floating plates" on the driver side for the door bar spacer tubes. we were going to keep going w/ the vertical bars in the door bars all the way to the rocker w/ floor plates on the ends of them resting on the rocker. the plates wouldnt be welded, just setting on top so as to not count as a mounting point. even that was getting alot of negative looks and feedback.

i think attaching the cage to select places like the windshild A pillar and main hoop to the B pillar are two places NASA is limiting cage safety. tying the cage to the chassis in as many places as possible is always cheap and safe.

keep in mind too, that the above cage was my first cage. Mitch and myself have changed things some since then and learned alot.

Dave, if you look at the 5th cage we built,Originally Posted by dirwin

We took advantage of what you are describing.

And while we were unable to attach a bar to the floor, we installed that 3rd bar down by the sill, just a couple inches off the floor. So after some deflection, the bar hits the floor and spreads the load just like an additional mounting point.

Dave - this is how we do them now.

Mitch & Glenn,

The red car's cage is outstanding. Load distribution is a product of a properly engineered cage. If a new builder doesn't understand the force dynamics involved in a crash and are not able to engineer the cage properly, DON'T build it yourself.

With our Mustangs, they are plated to the upper A pillar as well as both the upper and lower B pillar. We are able to get these through because they are Grand Am legal and were built by Multimatic.

It has always been my experience that if you bring up or propose an enhancment to safety and structural integrity to the scrutineers of both SCCA & NASA they will usually be pretty receptive. They will look and see if it is a performance advantage you are going for or if it is truly a safety issue.

Just another note. To tie the cage into the A & B pillar's is of no value if the pillars have been gutted for weight reduction as is very common with AI and A-Sedan. The only reason it works on the Grand Am car is the roof and pillars have been untouched and are still as delivered from the factory.

Again, I really like your red car, the workmanship and engineering look like they have been well done.

I appreciate those words. It takes time to build a "reputation" and it appears LAW Motorsports is headed in the right direction.Originally Posted by dirwin

It takes a LOT of time to buld a cage like that and close to a grand in nothing but materials. If I recall, there is 120' of tubing in Nick's cage. Last time we checked, DOM tubing was over $6 a foot!

Bookmarks